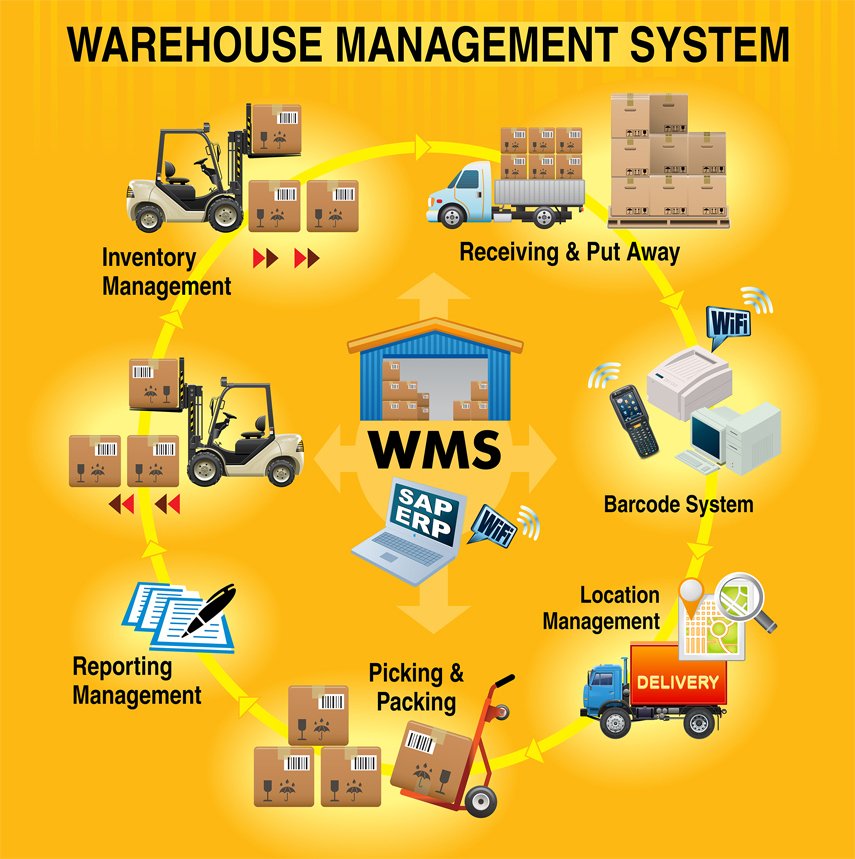

How Our Warehouse Management System Works?

Warehouse Management Service helpful in Industries Inventories Automation. For Easy Tracking & Measuring the Online status of Inventories, Warehouse Management Service is mandatory to perform quick management and activity tracking.

Security enters the information of received material into PDT. On completion, arrival register updated in the system. As a next step, material receipt gets updated in the system via Gate Arrival Log. Barcode labels are printed and pasted on these items. Finally, inspection is carried out and the status is updated in the system. Systm generates Pick list according to the store mapping. Pick list gets uploaded to PDA. Operator scans the bin bar code and confirms the picking process. Finally, material issue slip is generated.

Operators assigns the dispatch orders that need to be packed. They generate and paste barcodes on the box. Start scanning and putting material into box. Ater that, generation of carton-wise packing list for each dispatch order is done. 2D barcode is pasted on all the cartons that contain the entire packing list. Online updating of carton wise packing status for each dispatch order is done. After this segregation and packing, materials are loaded for dispatch.

What do you Expect:

As a company looking for warehouse management services, you expect:

- 100% accurate identification of spares

- Quick location and retrieval of parts

- The system should not hamper the speed of actions

- Ease-of-use for unskilled personnel

- Reduction in Inventory holding costs

- Integration into other systems, to avoid duplicate data entry

- Under High pressure during dispatches

How We Make Things Easy for You?

- Store organization and Mapping

- Material Receipt, Labeling and Acceptance in SAP

- Binning using hand held terminals and updating SAP automatically

- Generation of Material Requisition - Transfer Orders/Dispatch notes into SAP and updating the same in real time into WMS in real time

- Online assignment of pick orders to pickers and real time status to the supervisor of each pick list

- Picking and Packing - Simultaneously ...!!

- Barcode labels for each carton being packed

- Loading list for each dispatch and verification as materials leaves the warehouse.

- Physical Stock Verification and intra warehouse transfers

Barcode Technology Enables 100% Accuracy in Identifying Store Items

Managing a warehouse is a tedious task and comes with various challenges. If yours is a company where warehouse needs to be maintained and you face challenges like your SAP is prone to errors and not fully integrated, you remain under high pressure during the time of dispatch and your current system is not fully integrated. There are so many other challenges as well like your current system is not fully automated and there is a great variation in sizes and the nature of the spares.

Benefits of Warehouse Management Service:

With the help of tight integration of barcode technology, identification of the items is 100% accurate. You can check the online inventory status. It is a process-driven system and interfaces are available for the external system.